Urania Connections Home

Old Time Logging

by E. Forrest Cook

I got to thinking a while back about an experience I had in about 1938 when John Smith “Sonny” Bailey and I rode one of his father’s log trucks out to the Urania Lumber Company’s logging woods. At that time, the company still had its rail system and steam engines hauling from the woods to the mill in Urania. However, whether it was due to the timberland accessed by the rail system being depleted or because of economics, truck were being used more and more in order to supply the mill with saw timber. But possibly because the mill was sawing so much more, it was necessary to supplement the rail system with more and more trucks. Another reason I am sure, the company had purchased the timber lands which lay mostly in Northeastern LaSalle and Northwestern Catahoula Parishes from The Brown Paper Mill Company and those lands were not accessed by the rail system. I am not sure but believe that the company had not purchased the land in fee but only the timber rights from Brown.

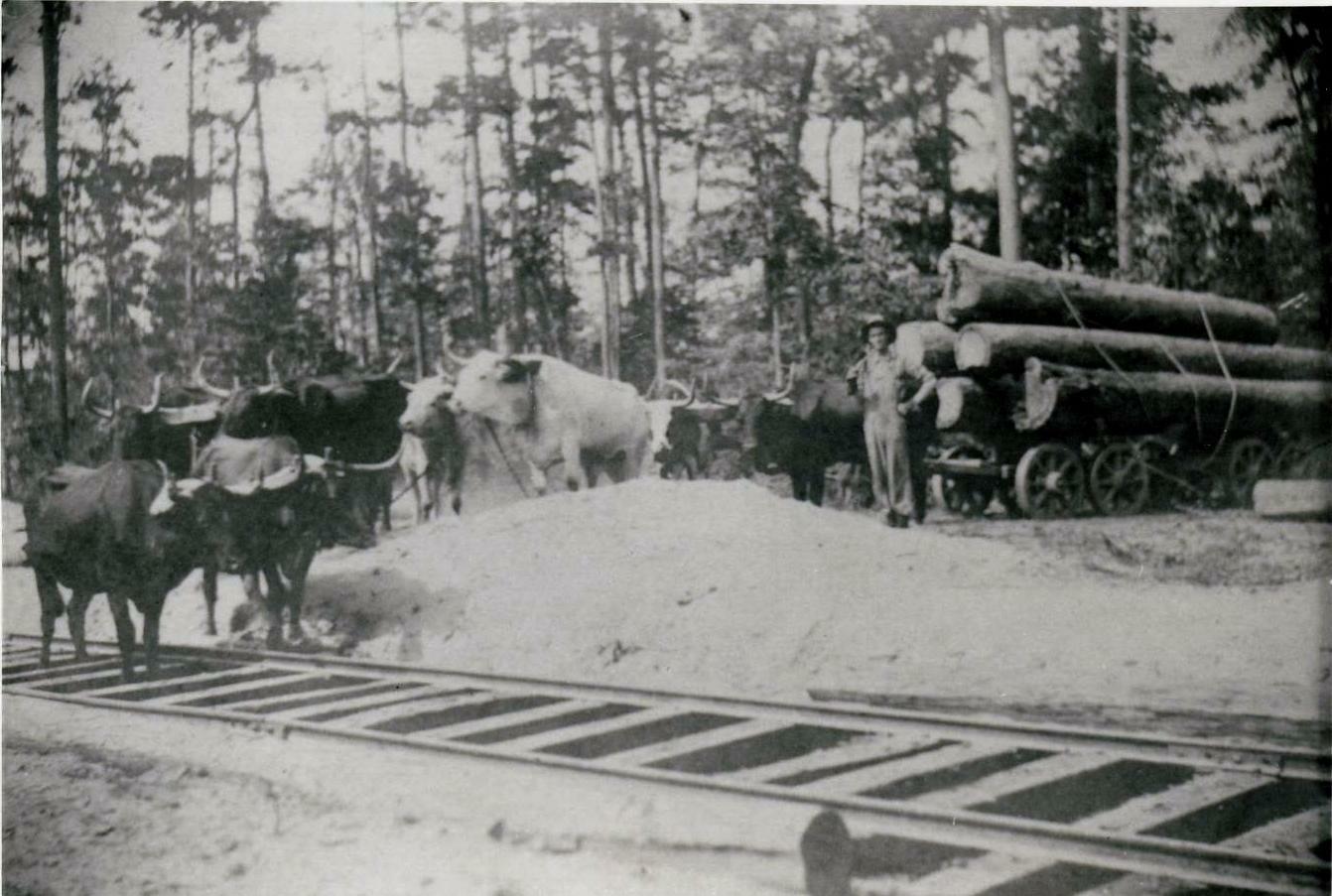

In the late 1930’s, the use of oxen, mules and horses in the logging operations was being phased out in favor of mechanized equipment. More on that later. When “Sonny” and I went this particular time, they were using 3 yoke of oxen, six huge animals probably weighing close to two thousand pounds each and my uncle, Glen McKeithen was the “bull pusher” or as it was called in some circles, the “bull skinner.” I am so very thankful that I was able to witness first hand, an operation that within a few short years was to be no more. I believe that the last animals used in logging by The Urania Lumber Company occurred in 1941 or 42, probably because of WW2 and also, the price of feed for the animals. Am sure that the availability of more and better mechanical equipment also entered into the decision.

I will attempt to explain the method used to load the truck, hopefully future readers can understand how the system worked. First, the log trucks in those days were a lot smaller and less powerful that those used these days. (2009) It usually consisted of a Ford V-8 truck with single dual wheels and the trailer connected by a four inch pipe to the truck, also single dual wheels. The bolster was of an H-Beam of about eight inches in height and eight feet in length, or I suppose one could say in width as that was the support for the logs. The bolster on the truck was connected by a pin which allowed it to swivel and of course, the pipe (coupling pole) was connected to the truck bolster and that allowed the two bolsters (truck and trailer) to stay parallel as curves were negotiated.

In order to load the truck with the oxen, one yoke was disconnected from the other two yokes and used in the following manner, IE: skid poles made from oak saplings and about ten feet long were placed on the two bolsters, truck and trailer. A long chain was then connected, each end to the truck and trailer frame and it was then placed over the notched ends of the skid poles and laid out in a loop on the ground, thence a log was rolled over the loop with a canthook, another chain was run over the log and hooked to the looped chain that was under the log. That chain was over the trailer coupling pole and hooked to the yoke of two oxen, Uncle Glen was squatted down by a nearby pine tree and he would talk to the oxen; they knew exactly what to do. When he told them to, they moved forward, thereby rolling the log up the skid poles until it came to rest on the truck and trailer bolsters and when that happened, the oxen knew it was time to stop. He told them (I am not sure what words were used) and they would back up while the men would pull the chains back, unhook the one connected to the oxen, lay the loop out on the ground again, roll a log on the loop and the operation was repeated. Once the bolsters were full of logs, the skid poles were then placed on the logs and other logs rolled in between that layer, then repeated for each successive layer until the truck was loaded. Once the truck was loaded and if the ground happened to be wet, which it often was, all three yokes of the oxen were hooked to the truck to assist and once approximately 12,000 pounds of beef was applied, the truck was going to move or something had to give.

I realize that it might be hard for a person reading this at some future time and never having experienced this form of logging to visualize how it was carried out. Consequently, I am attattaching the following two photos:

This picture gives details of the log trucks and method of rolling the logs up onto the truck. Notice the chain attached to the truck and trailer; thence over the ends of the skid poles, and under the log. Then, the chain hooked into the “loop chain” and attached to the power to roll the log up and into place. In this photo, a caterpillar tractor was being used but the principal is the same whether oxen, mules or horses were used.

This picture gives details of the log trucks and method of rolling the logs up onto the truck. Notice the chain attached to the truck and trailer; thence over the ends of the skid poles, and under the log. Then, the chain hooked into the “loop chain” and attached to the power to roll the log up and into place. In this photo, a caterpillar tractor was being used but the principal is the same whether oxen, mules or horses were used.

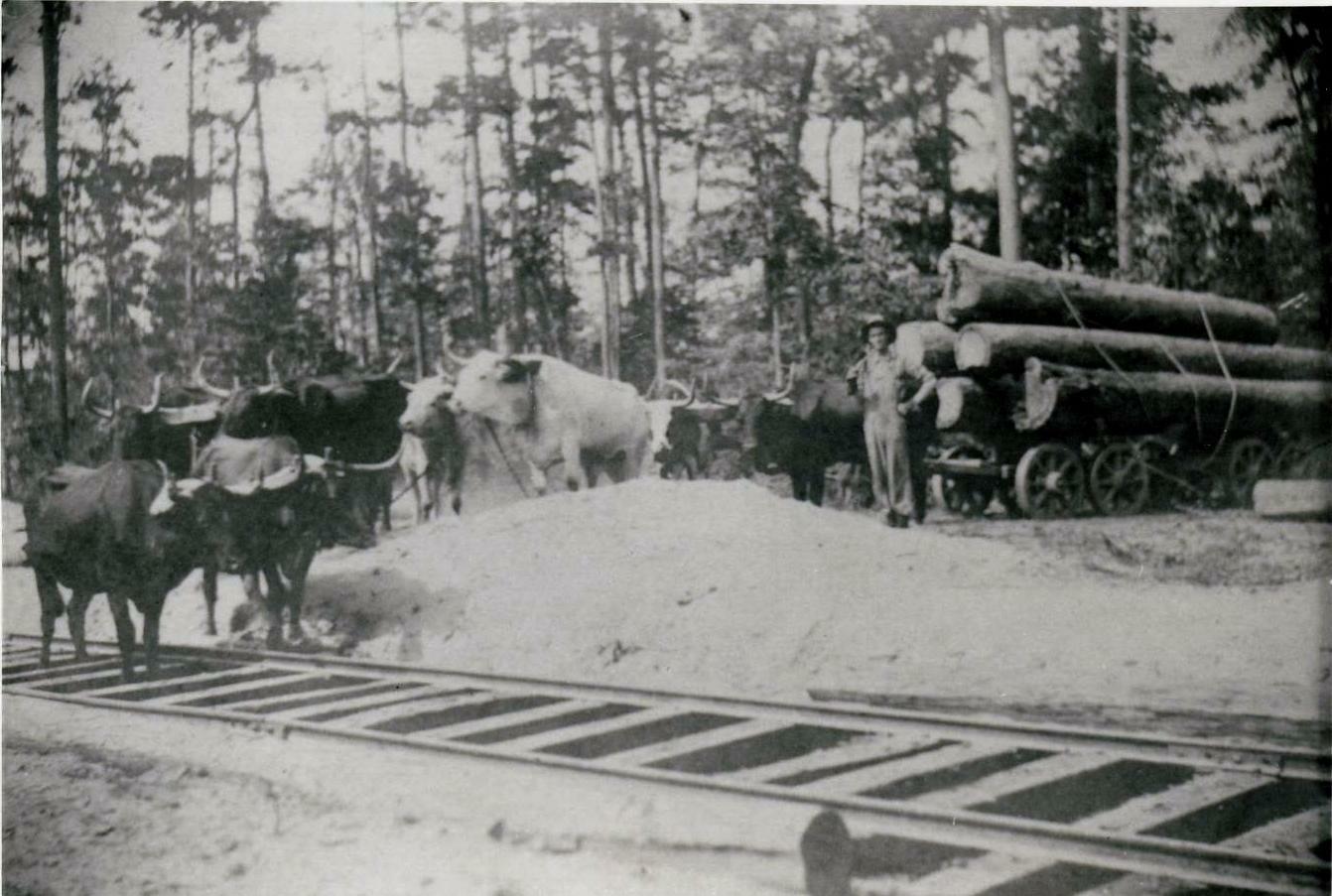

In the following photo is an example of yoked oxen being used for the power source. The day I witnessed the operation, only one yoke was used but I assume the number being used depended on the size of the oxen as well as the logs being loaded.

Logging by Rail

I was told this story by Grady “Bud” Hinton several years before his death. “Bud” said that sometime after Henry Hardtner bought out the Prestridge’s sawmill in 1898, he wanted to expand the operations but was limited by the amount of saw logs that could be gathered as most of the timber in the vicinity of the mill that could be easily harvested using animal power had been cut. He was on a train to New Orleans to try and borrow money to install a logging rail system in order to supply the ever growing sawmill when he chanced to meet Mr. William Edenborn. Mr. Edenborn, a self made millionaire in the barbwire business had acquired/built the Louisiana and Arkansas Railroad and the Louisiana Navigation System. The L & A, with the motto “The L & A, the Better way” ran from Vidalia, Louisiana to Arkansas, El Dorado, I believe. It ran through Jena, Georgetown, Packton, Winnfield, Calvin, Goldonna, Chestnut and points East and North. Their main repair shops were in Minden. Webster Parish.

It seems that Mr. Hardtner, being of German descent as was Mr. Edenborn approached the latter for a loan in order to construct the rail system whereas he was told that he could not have a loan but Mr. Edenborn agreed to buy stock in the company in order to effect the building of the rail system. And I assume that he continued to be a partial owner in the company until his death. The L & A story is intriguing and I have a book about it and William Edenborn published by The University of Indiana Press.

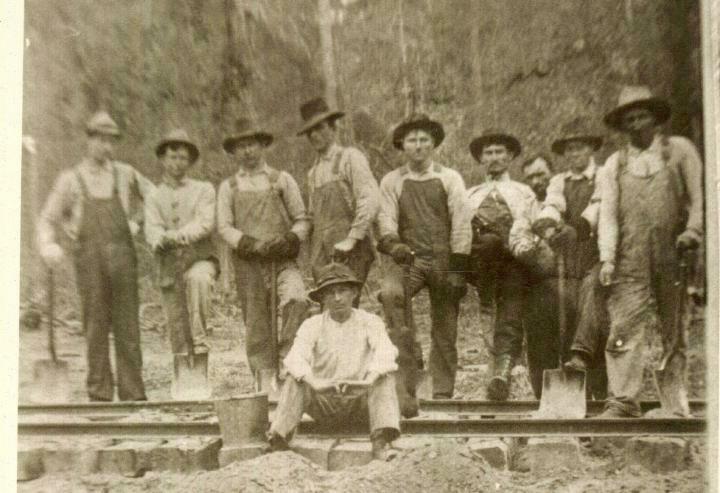

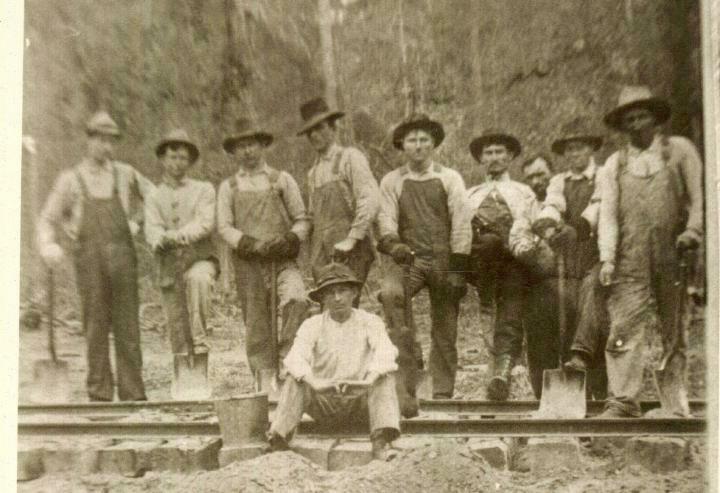

With that, the Natchez, Urania and Ruston Railway was established and I assume that the charter allowed a road to be constructed to those points but in reality, the only semi-permanent line was from Urania to the Hinton Camp with a branch off that connecting to the Missouri Pacific System in Olla. From that line many temporary branches were constructed to the various plots of timber and as soon as an area was cut, the rails were picked up and moved to another location. This was accomplished by a crew called the “snipe crew”. And I have never been able to determine why they were called that? Here is a picture of the bunch that picked up and laid the temporary tracks; the only one identified is the tall man standing back of the man sitting and he is George Hatten.

Loading on the Log Cars

After the N U & R Railroad was constructed in the early 1900’s, probably around 1906 or 07, the manner of getting logs to the rails was by a re-haul unit and I have a photo of it but after an exhaustive search of my files, can not locate it so I will attempt as best as I can to describe that operation. I am not sure how the unit was attached to the railroad but logic tells me it had to be: it was in a building like structure, between thirty and forty feet wide and about twenty feet deep. It had two beams of around twenty feet in length from each front corner at an angle of some 45 degrees. At the end of these beams was attached a large pulley and through that was a wireline (cable) attached to separate winches inside the structure, one for each beam. Those winches were powered by a steam engine, the steam produced by a boiler set between the two winches and probably fired by locally acquired pine knots and other scrap timber.

The wirelines could have been around 1000 feet each in length and while the winches were in neutral, were pulled out by the oxen, horses or mules. Once out, there would be several logs attached and the cable reeled in until the timber was adjacent to the rails and thence, loaded onto log cars.

It has been my supposition, confirmed by Glen Dale McKeithen that this method wasn’t used very long due to the danger to men and animals as well as destruction to small timber and seedlings. Since the Hardtner Brothers were some of the first people to stress reforestation in Southern Forests, they naturally wanted natural reseeding of pine timber to prevail. And that really paid off in later years as it has been said that The Urania Lumber Company was growing more timber that was being harvested. The next method of getting timber to the rails was by log wagons pulled by either oxen or mules as indicated below.

It must have taken much patience and skills to train the animals to be so obedient and to follow spoken orders.

Once the logs were spotted near the tracks, the loaders then took over. They were of course, steam operated and in the beginning a loader was used that required the individual empty log car to be taken from a temporary siding, backed in to the loader and when loaded, taken to another siding, unhooked from the engine and another empty taken to the loaded and etc. As indicated in the following photograph.

One can readily see just how time consuming such as operation would be and since time is money, you can bet that the brothers Hardtner put their minds and finances to work to rectify the situation.

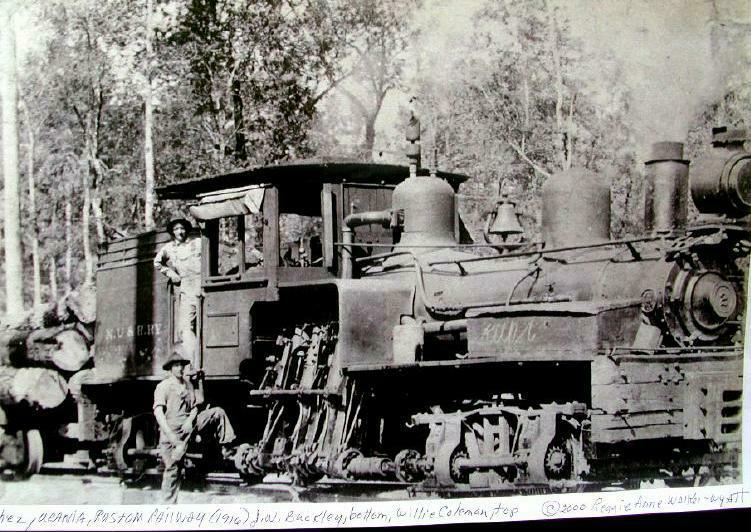

But first a word about the gathering and bunching loaded log cars for the eventual transporting to the sawmill in Urania. The train engine used in the woods to do that job was a Shay in which the operating system was completely different from the normal locomotive with which we are all familiar. The reason for using a Shay was the fact that while being quiet slow, they were also very powerful and could be used on substandard rail systems that the mainline locomotives could not negotiate. In place of having steam pistons connected by linkage to the wheels, the Shay had three pistons with the connecting rods coming out of the side of the engine. Those pistons worked in the same fashion as your normal automobile engine, IE: turning a crankshaft running the length of the locomotive which was geared as were the engaged wheels, thereby transferring power to move the train.

The Shays would work the log cars for the loaders, and then bunch the loaded cars on a siding off the main line near the Hinton Camp. Thence, the mainline locomotives would collect the cars and deliver into the mill in Urania.

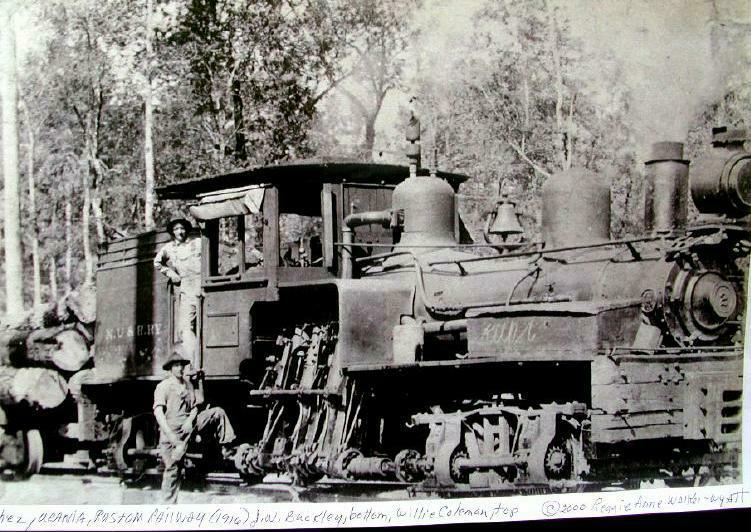

Here is a photo of the NU & R Number 5 spot Shay which that gives a good illustration as to how engine was powered.

And now, I want to interject a bit about the engines that hauled the loaded log cars from “the front”, as the log woods were referred to, into the sawmill in Urania. Not knowing for sure but logically, the first mainline locomotive acquired by the company would have been numbered one since the two subsequent ones were numbers two and three. And the engineer for number one was Jake Posey; I guess you could call him the “Urania Casey Jones.” On the morning of August 10, 1917 Jake and number one headed to Hinton Camp with a string of empty log cars and aboard the train with him and his fireman were Mrs. Pallie Peevy and her three young sons Harold, Horace O. and Laval O. How thrilled those three youngsters must have been to be able to ride to Hinton and back with that fabled engineer, Jake Posey! They were to spend the day with Pallie’s sister, Nora Allie Peevy Hinton, wife of Grady Hinton, Sr. and return to Urania with Jake on his second run in the afternoon. As heretofore stated, Grady ran the commissary (company store) at the camp.

In 1917, the NU & R did not have a Y side track in order for the engine to turn around: absolutely necessary turnarounds were accomplished by getting on the Missouri Pacific (now Union Pacific) lines from the connecting siding in Urania and going to Rochelle, there using the Tremont and Gulf Y turnaround. Then again time and money and in addition, making arrangements with Missouri Pacific for permission and times to travel their rails probably was the reason that Jake’s request to do that was denied. Consequently, it was necessary for him to travel one of the ways to or from Hinton backwards.

It has been reported that Jake was ticked off about that to begin with and also, there were more loaded cars than normal waiting to be picked up. So he hooked onto the loaded cars with the front end of his engine, loaded up Mrs. Peevy and her three sons and headed for Urania. On the line from Urania to Hinton there was a place called The Kansas City Cut and the reason for that name was a large object was being hauled to the front and in this cut, it was too narrow for the object to pass so the right of way had to be widened at that location. At the cut there was quiet a steep grade and Jake had poured on the steam in order to get over it and as he approached it, the tender which was ahead of the train began to sway from side to side and then jumped the track. That caused the engine to also leave the track and overturn, trapping Jake, Mrs. Pallie and her three sons in it; the boiler burst and scalded the four of them. The fireman, one Willkie Coleman saw what was happening and jumped clear and was basically unhurt. Incidentally, Willkie is the man standing in the cab of the Shay Engine featured earlier and the man on the ground in that picture was John Buckley who later was an engineer on the mainline trains for many years. Pictured below is the result of that tragedy.

Mrs. Peevy and her three sons are buried in the Urania Cemetery in a common grave and Jake is buried at New Union Cemetery between Urania and Tullos.

Because of this event the company built Y’s at both Urania and Hinton so the trains could always travel in a forward looking configuration.

Now, back to the loaders. Since the aforementioned method of loading logs onto the cars was so time consuming and costly, the company purchased a McGifferet loader and the advantage of such a loader is readily apparent in the following photo. Simply, the wheels could be contracted allowing log cars to be pulled or pushed underneath and eliminating the need to shunt cars back and forth but just to move one ahead, load it and then move the next one in line into position. In addition, the wheels were connected to a gear on the engine above by a chain and when lowered, could move under its own power thereby eliminating a train having to be in attendance during such moves.

McGiffert Loader

Now that we have discussed the loading of logs from the woods, let us talk about unloading at the sawmill. Prior to ca 1925 the mill was configured facing North with log ponds between the mill and town but around that time, the mill burned and was rebuilt. The later mill was completely reversed with the logs being transported up into the mill from the South side. In the older mill, the logs were unloaded into a pond and from there carried into the mill for sawing by a trough and a chain which was a good 12 inches wide. The method of unloading the log cars was unique as one of the rails was a couple feet above the other; the chains were removed from around the load and as the cars were backed over this inclined rail, gravity took over and the logs were dumped into the log pond. In the following picture, it is hard to tell that one rail is elevated but you can see the string of log cars with those on the right still loaded and those on the left emptied as they have been backed over the inclined rail. And you can see the trough going up into the mill that carried the logs.

Let’s talk a bit about the operations of the mill and I have no knowledge of the one shown above other than what the picture shows but am familiar with the new one from my own observations. I never worked there except a short time in early 1946 after WW2 when I was discharged from the US Navy and before starting school at Louisiana Tech in Ruston. My father, Hardy Maxwell Cook who was in charge of the boiler room and power plant had been to Yale Lock Company and purchased three used steam turbine generators which were being installed. Two 1000 KW and one 750 KW unit which fed power to the mill operations and during off-peak hours, fed electrical power back into at that time the Louisiana Power and Light grid; now Entergy Company. And I helped with that project.

Steam was produced by five huge water tube boilers using sawdust supplemented by natural gas from a nearby well. These boilers were in continuous operation around the clock 24/7 and in addition to furnishing steam to run the generators, also to run a huge steam engine furnishing power to the mill by a system of shafts, pulleys, gears and etc. In addition, steam to heat the dry kilns as well as a myriad of pumps and other devices throughout the sawmill itself. Power for the planer mill was by electricity, it being situated away from the sawmill by a few hundred feet.

The sawing was accomplished by two carriages which would take the logs from the trough, attach them by a series of spikes (called dogs), moved on rails and the logs were sawn by huge circular saws measuring about ten inches in width and around 40 feet in length. It was a very fast operation and mesmerizing to watch with much noise accompanying.

After the log was squared to the right dimensions, that timber went through a gang saw that sliced it into planks which went via a the green chain to be sorted and stacked for the dry kiln. After drying, the lumber was put through the planer mill, then sorted again and stored in huge sheds appropriately called the dry sheds; there it stayed until shipped by either trucks or boxcars. Some day I plan to write an article describing the mill operations in more detail along with pictures but that’s for another time. Following is a photo of the unloading of logs after the new mill was built. It was accomplished by a stiff leg crane as shown.

Notice the tank cars in the far right of the picture. They are on a siding of the Missouri Pacific Railroad and that siding was connected to the NU & R tracks so the various types of train cars could be shipped with products from the mill.

I have heretofore mentioned the two steam locomotives for the Natchez Urania and Ruston Railroad, they being numbers 2 and 3 so let’s take up on those once again. It is assumed that number 2 was acquired soon after the Jake Posey wreck of number 1 in 1917 but no one in this time could tell you where and how it was acquired. I am reasonably sure that it was bought used and quickly as the mill depended on the railroad for its supply of timber. There is a logical assumption that they used the Shay to not only work the log woods but to also, bring the log cars into the mill. That would really impact the supply and since the Shay was not only slow but doing double duty, am sure that it cut the logs delivered to the mill in more than half. I am guessing that number 2 was purchased from another nearby lumber company or maybe from The L & A Railway but we will never know for sure as all the records of the company were destroyed in a fire that completely consumed the main office in around 1965.

Number 3, a Baldwin 2-8-0 however is a different matter. We know from handed down stories that Dally Chapman was sent to Cuba, purchased the engine from a sugar mill, loaded it onto a barge to New Orleans and from there brought to Urania via existing rails. As the story goes, when Mr. Chapman went to Cuba the owners of the mill had a better offer and offered him $1000.00 cash to advise the company it wasn’t suitable; he declined.

There was one other way in which timber was harvested, usually trees struck by lightening or bug infested or died from other causes and within a few miles of Urania. That was by horse and log wagon. One would normally think that mules would have been used for that job but not the case. Mr. Willie Thornton was in charge of that operation and as you can see from the following photo, had a 4-up team of fine horses. I can remember seeing that coming into Urania, another scene that I am thankful that I was allowed to witness.

I am reasonably sure that this picture was taken about 1938 as there is a 1936 Ford Convertible parked under the shed at the commissary. Also, am reasonably sure that the man standing next to the hollowed out cypress was Professor Chapman from the Yale School of Forestry as the photo was taken by one of the Yale students. That is another project in mind for the future, writing about the Yale University classes that came here every summer to study as well as do forestry work for the company. There was a camp just out of town and this is a story that few people are aware of in this day and time. (2009) BTW, that cypress was used by the man who scaled the logs brought in by trucks as well as the night watchman.

That is of course, the company commissary in the back ground. The ground floor was occupied by a drug store (no medicines as that was furnished by the company doctor) which sold notions and etc, and some of the best nickel icecream cones that could be gotten anywhere. There were men and ladies clothing, groceries, meat market and small hardware items. The middle floor mezzanine was used for storage and on the top floor there was a Masonic Hall. To the left of the picture is the Ford Motor Company, service station and garage.

Return to Urania History Home

This picture gives details of the log trucks and method of rolling the logs up onto the truck. Notice the chain attached to the truck and trailer; thence over the ends of the skid poles, and under the log. Then, the chain hooked into the “loop chain” and attached to the power to roll the log up and into place. In this photo, a caterpillar tractor was being used but the principal is the same whether oxen, mules or horses were used.

This picture gives details of the log trucks and method of rolling the logs up onto the truck. Notice the chain attached to the truck and trailer; thence over the ends of the skid poles, and under the log. Then, the chain hooked into the “loop chain” and attached to the power to roll the log up and into place. In this photo, a caterpillar tractor was being used but the principal is the same whether oxen, mules or horses were used.